Generally speaking, the insert should extend a minimum of 0.016” (0.4 mm into the cavity of the mold), and, in order to prevent sink marks in the plastic, the molding beneath the insert should be a minimum of one-sixth the insert’s diameter. A good rule of thumb when designing inserts is to ensure that they stay small relative to the

Insert molding is the process of making a plastic mold and inserting another piece, typically metal or other material, into the mold. The result is a custom component with precisely aligned pieces. An insert mold requires specialized equipment and engineered plastic components. A standard molding machine won’t offer the convenience or

250ul insert, polypropylene w/grad 100pk Add to Favorites + Create New list Item successfully added to your list List Price: $37.60 /100 Pack Add to cart Please enter valid quantity Specifications UNSPSC Code Create a List List Name * List name is

Insert Injection Molding could be called Insert Molding or Over Molding, which a sole part is formed using two or more different materials in combination. In Insert injection Molding can either be incorporated at the time of the molding process or can be inserted as post molding operation.Especially, if properly selected two kinds of material, it will obtain a strong bonding of

Various types of inserts come with their own benefits and drawbacks, so contact Romeo RIM today for help deciding just which insert is right for your next project! 74000 Van Dyke Ave, Romeo, MI 48065. 586-336-5800 Mon-Fri, 8am until 5pm EST. sales@romeorim.com We reply within 48 hours. Tags: Insert Molding.

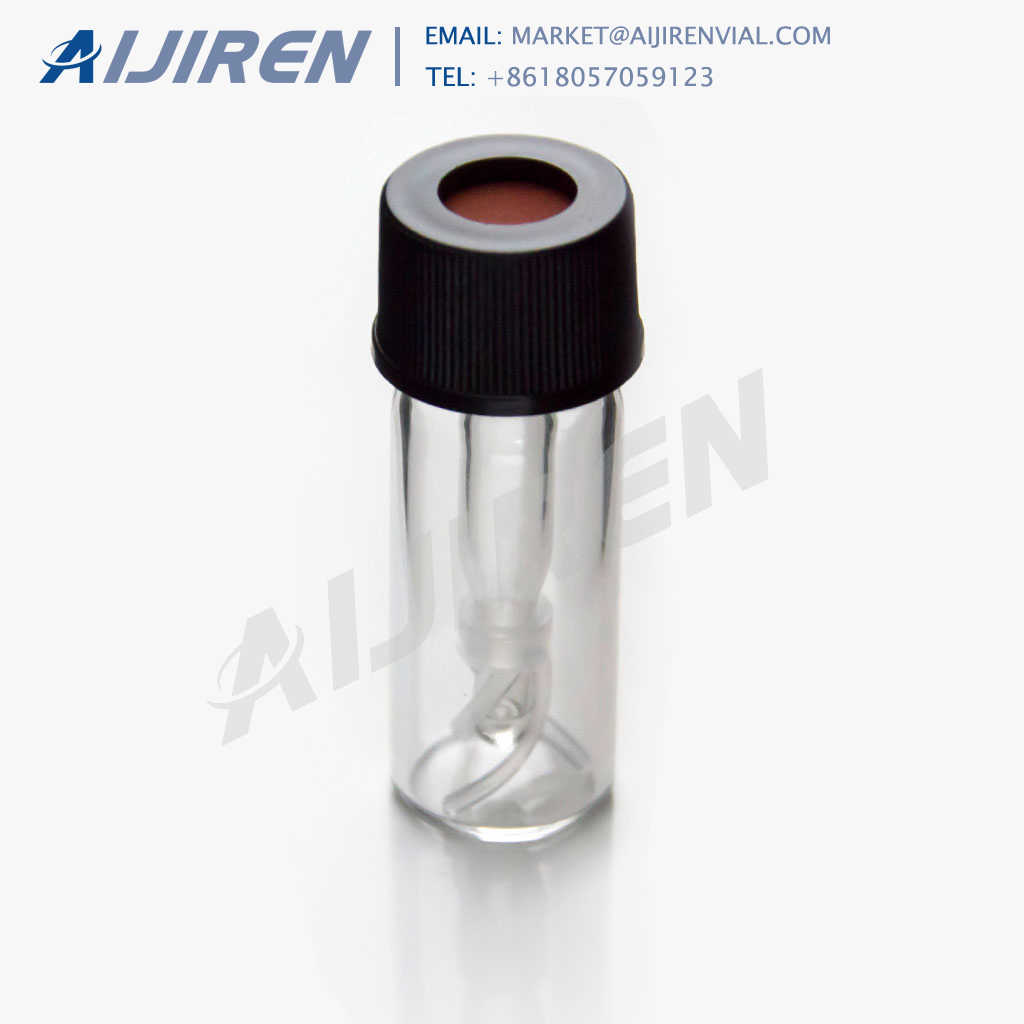

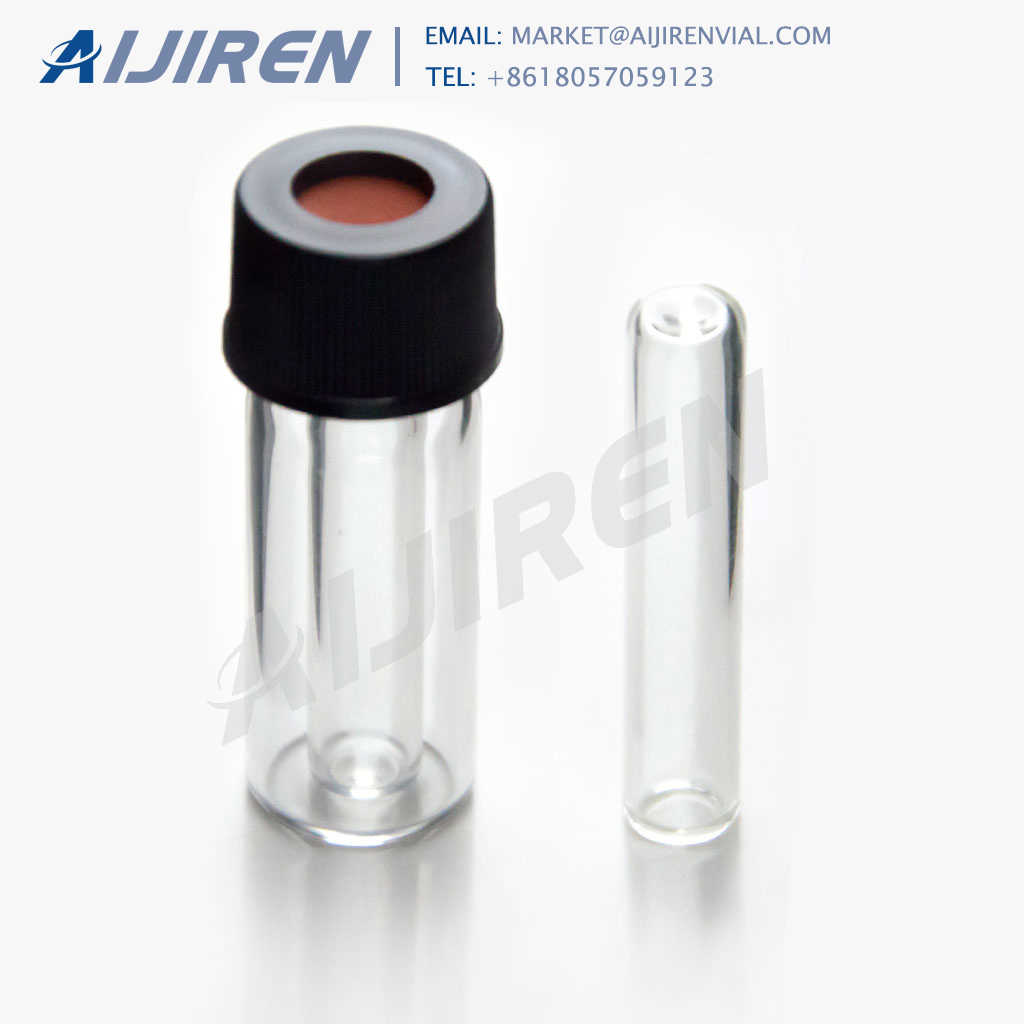

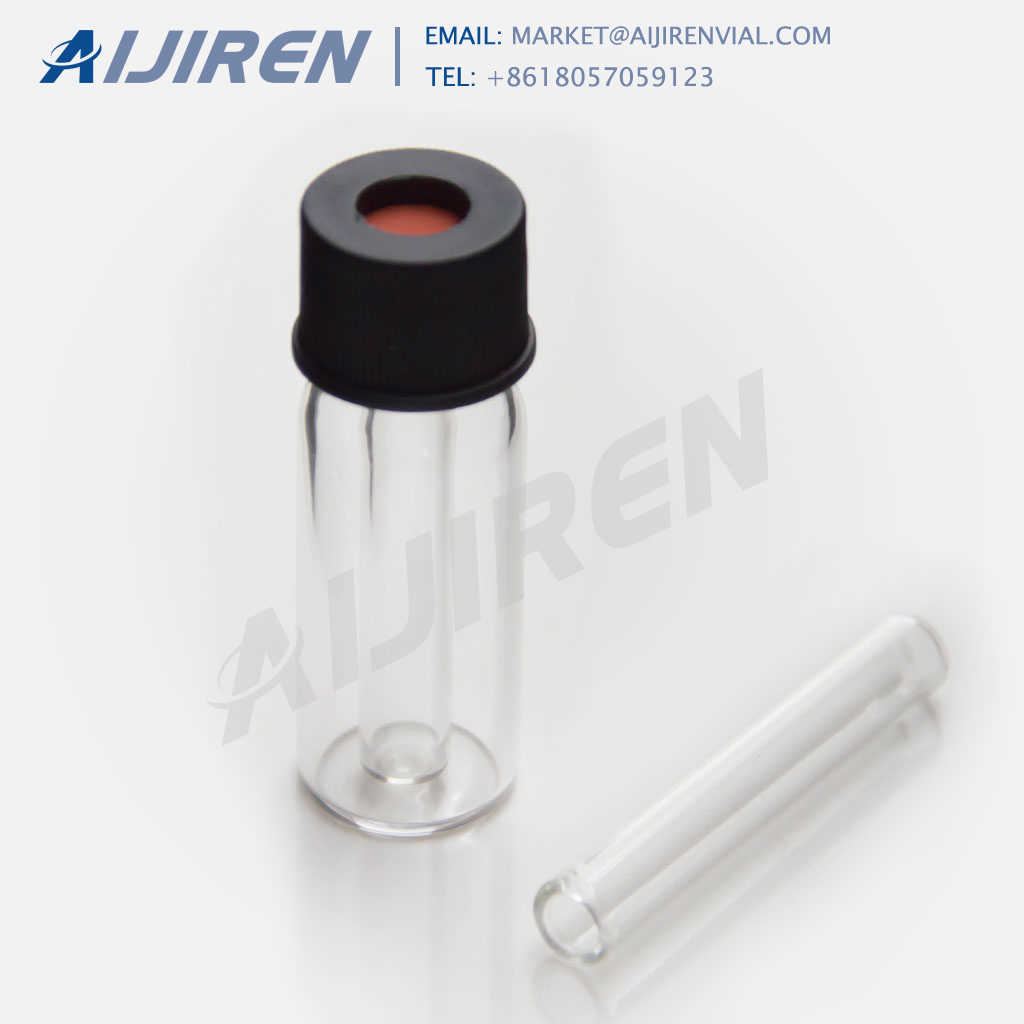

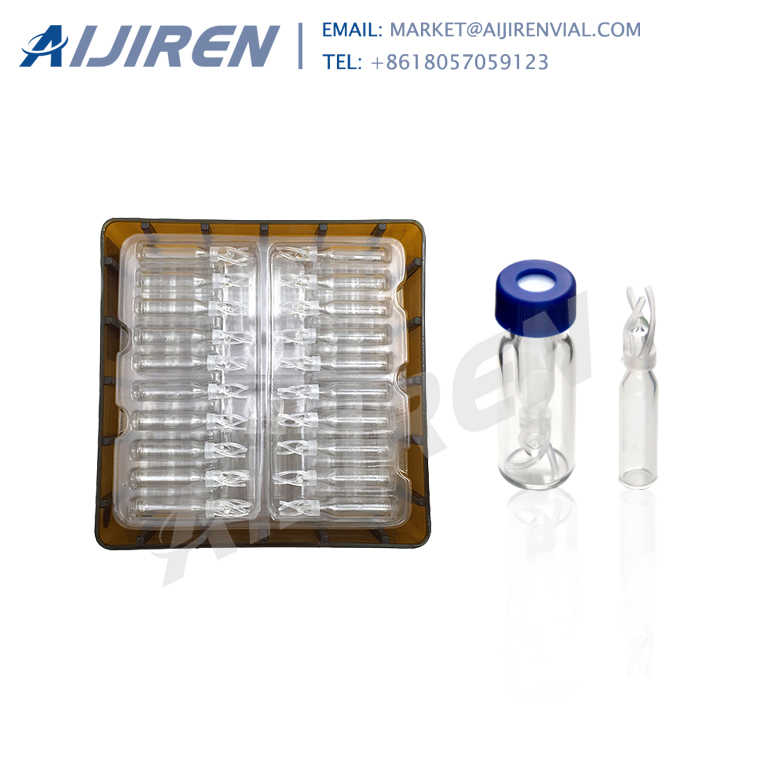

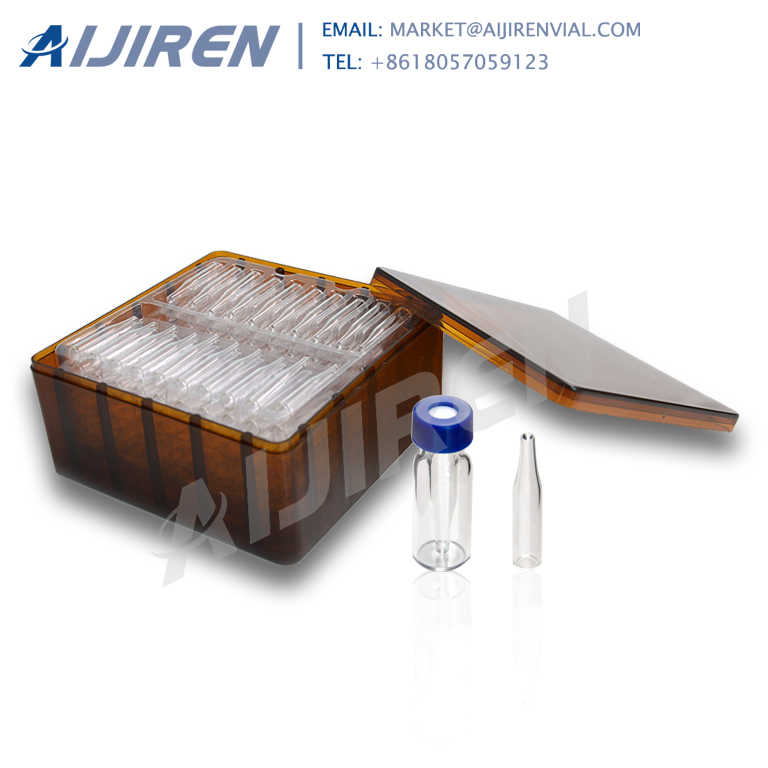

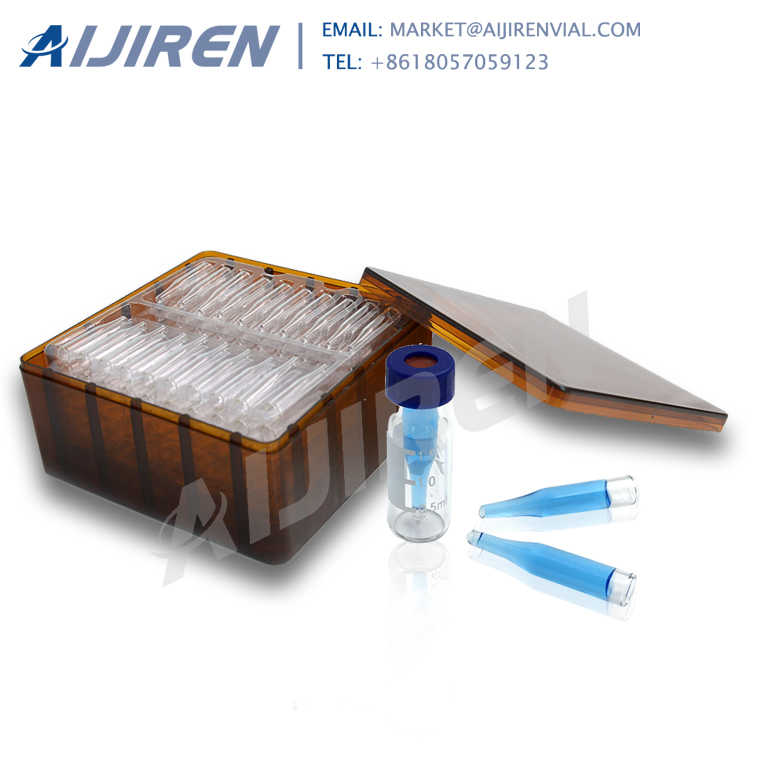

250ul micro insert - 2ML-N2002 - Aijiren (China Manufacturer 250ul micro insert 2ML-N2002 - Aijiren Products Made In China, China Manufacturer. 2ML-N 2 002---6x28mm Insert, Clear Gl Application: Suitable for 8-425, 9mm, 10-425, 11mm snap vials Material

2019/6/29 · The “magical” process that makes connectors, grommets, strain reliefs, and plugs are called INSERT MOLDING, a special niche of injection molding. In the simplest sense, insert molding is done on an injection molding where you mold plastic around an object that has been placed in a mold. The final product is determined by the shape of the

2021/7/1 · In this episode Gordon discusses the difference between Insert Molding and Two-Shot Injection Molding (aka) Overmolding (aka) 2K Molding, their advantages an

2021/3/6 · Essentially, you can get a 062″ diameter O-ring cross-section in the price tag of $1500 for a single cavity. Moreover, a two-cavity silicone injection mold can cost up to $2000. Molds for a complex gasket with undercuts along with complex geometry for insert and over-mold processes will charge you a cost of $6000 to $7500.

250ul PP Insert w/bottom spring 6x31, case/1000 250ul Clear Insert w/bottom spring 6x29, case/1000. List: $354.00 $329.47. Add to Cart. Quick view. Worldwide Glass Resources | sku: WWG-20051. 250ul Clear Insert w Insert Molding: How to Ensure

Caps are made of high quality polypropylene to exact manufacturing tolerances and lined in a controlled manufacturing environment. suits for ND8 Vials IPB250 29*5.7mm 100PCS/PK 250ul Insert with mandrel interior and polymer feet, 29*5.7mm; suits for ND9

2021/11/19 · Film Insert Molding (FIM), also known as INS, is part of In-Mold Decoration. A technology that allows you to put virtually anything you want on a plastic component. The pre-printed film (or foil) is inserted into the mold cavity and thermoformed, which combines the advantages of decorative and functional graphics with a plastic molded component.

2021/12/15 · Step-by-step Guide to install Brass Threaded Inserts for Plastic Injection Moulding. Learn from the experts how to use brass threaded inserts for plastic in day-to-day life. sales@shivrajbrass.com +91-9033640704 Search Search

Insert Molding Analysis, Mold Insert, Injection Molding Table 1. Insert materials list Insert # Material Cp (erg/g.K) K (erg/sec.cm) 1 P6 4.6e6 4.7e7 2 Beryllium_Copper 1.9e7 1.5e7 3 Polymer 2.3e7 2.4e4 Figure 1. Computational framework of 3D injection

2022/8/17 · Several insert molded screwdrivers. Overmolding is an injection molding process that creates parts from two or more materials. It is sometimes referred to as “in-mold assembly.”. Overmolding can be roughly divided into two distinct processes, insert molding and multiple-shot molding. Insert molding (sometimes spelled insert moulding) is